Call Now:

518-424-2258

Services

Concrete Floor Services

Polished Concrete

Polished concrete is a multi-step process that utilizes diamond impregnated abrasives and chemical hardeners to produce a hard, durable shell. Each piece of concrete is unique with no two pours being identical. Specialized industrial equipment outfitted with diamond abrasives are used to remove surface imperfections and refine the concrete’s surface. More aggressive course grits are used initially and are followed by progressively finer grits in order to smooth the floor.

A penetrating sealer is then applied in the middle of the process to harden and add density the concrete. This is an internal reaction that builds a crystalline structure in the air voids of the concrete’s surface. The polishing continues with finer abrasives. The level of sheen can be varied by the last grit of abrasive used. Bottom line: The finer the grit, the greater the shine and clarity. If you prefer colored concrete, pigments can be introduced into the process with the use of concrete dyes. Borders, patterns, logos, and various designs can be utilized to produce a unique, customized appearance. Decorative cuts and engraving can be incorporated to provide further enhancements. Polishing concrete can be used to revitalize existing concrete or beautify new concrete.

Applications for Polished Concrete:

- Warehouses

- Retail Spaces

- Restaurants

- Showrooms

- Office Buildings

- Private Residences

- Radiant Heat Floors

Benefits of Polished Concrete:

- Superior Durability

- Ease of Maintenance

- Lower Life Cycle Cost

- Environmentally Friendly

- Eliminates Need for Coatings or Waxes

- Dust and Allergen Free

- High Light Reflectivity (Less Need for Artificial Light)

Polished concrete provides an extremely durable flooring solution. Your long-term satisfaction requires implementing a proper maintenance program. We are happy to work with you to custom design a program to ensure years of enjoyment with your polished concrete floor.

Decorative Overlays

Concrete overlays can transform your boring old concrete into a beautiful work of art. An overlay system involves polymer-modified, cement-based products that can be installed in thin applications or built thicker to accept a stamped texture. Overlays are more durable than conventional concrete and offer superior strength. Texture, pattern, color, and design possibilities are virtually unlimited. Stencils can be used to create anything from logos, borders, decorative accents, and patterns. With overlays, you can even have your concrete resemble a gorgeous Persian rug.

Types of Overlays:

- Spray Down – offers superior slip resistance

- Trowel Down – offers a variety of textures ranging from smooth to a rougher, more Tuscan look

- Stamped – creates a stone-like appearance

Concrete Overlay Applications:

- Sidewalks

- Patios

- Pool Decks

- Basements

- Driveways

- Retail Stores

- Office Buildings

- Restaurants

- Schools

We can help create a one-of-a-kind floor to suit your specific needs. Don’t rip out and replace your old slab or hide it with a conventional floor covering – allow us to design a unique concrete surface custom designed just for your project.

Stains and Dyes

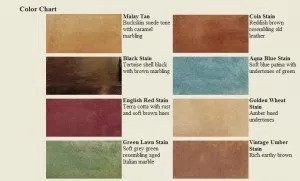

Stains create a unique mottled, variegated appearance on concrete. Acid stains are water based acidic solutions that contain metallic salts that react with the concrete’s free lime. The acid opens the concrete’s surface pores and allows the metallic salts to penetrate. The resulting color will not chip off or peel and is UV stable. Acid stains typically come in approximately 8 earth tone colors in the black, brown and blue/green families. Stains are also available in water based formulas. Water based versions offer a wider range of more vibrant colors.

-

Title

Button

Dyes

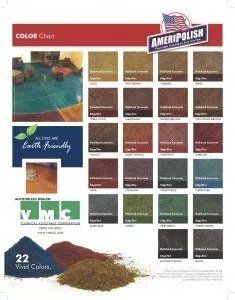

Dyes are finer in particle size than stains and allow for easier penetration of color. They can be used alone or in conjunction with stains to provide a larger palette of colors. Dyes are typically more vibrant in colors and can be used full strength of diluted to create different shades. Dyes work extremely well with polished concrete indoors but do not work outdoors as they are not UV stable. Dyes are applied to structurally sound concrete and can be blended and diluted to achieve a wide range of colors. Here is a color chart that you can enlarge by clicking to see the different options.

-

Title

Button

Garage Coatings & Decorative Epoxies:

In the northeastern states, the biggest enemy of your garage’s concrete floor is road salt intrusion. Sooner or later, all untreated concrete will begin to pit and spall when exposed to road salt. At Specialty Concrete Systems, we can provide protection against salt, oil, gas, and chemical penetration with the installation of an epoxy flake system. We start by grinding the concrete with diamond abrasives to remove contaminants, open the surface pores, and smooth the surface. Any necessary patching and repair is then performed. An epoxy body coat with a vinyl flake broadcast is then applied. The vinyl flake comes in a variety of color combinations and provides improved aesthetics, as well as slip resistance. Two clear topcoats of polyurea are then applied to provide superior protection and abrasion resistance. Our garage coatings will provide you with a durable, stain-resistant finish to protect your concrete for years to come. We supply all of our customers with a 30” neoprene squeegee to assist in keeping your floor clean.

-

Title

Button

Decorative Epoxies

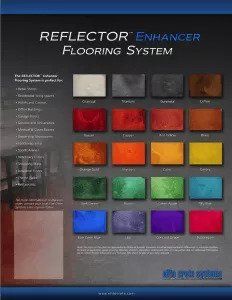

We can provide you with a one-of-a-kind floor with the use of decorative epoxies. We use Elite Crete’s Reflector metallic powders to produce eye-catching designs and colors to transform plain concrete into a work of art.

Densifying Hardeners

These penetrating chemical sealers produce a chemical react with the concrete to permanently harden, densify, seal and dustproof your concrete. There is no membrane coating to wear-off or maintain.

CONTACT US

Please fill the below form for FAST & FREE quotes.

Contact Us

Thank you for contacting us.

We will get back to you as soon as possible

We will get back to you as soon as possible

Oops, there was an error sending your message.

Please try again later

Please try again later

Specialty Concrete Systems | Rexford, New York 12148 | PH: (518) 424-2258 | FAX: (518) 280-1049

Albany, NY | Glens Falls, NY | Clifton Park, NY | Saratoga Springs, NY | Schenectady, NY | Troy, NY | Rexford, NY | Colonie, NY

Website Design

by Hearst Media Services, all rights reserved